7 Step Repair Process

After collection of the bit the process of inspection and repair will start. Mud and grease will be removed in a special designed washing machine with a mix of water and detergent at high temperature.

For the next step in the cleaning process a blaster is used. Small particles at high air pressure are used to remove the last dirt. All dirt for the cleaning process is collected, treated for re-use or collected by specialized companies.

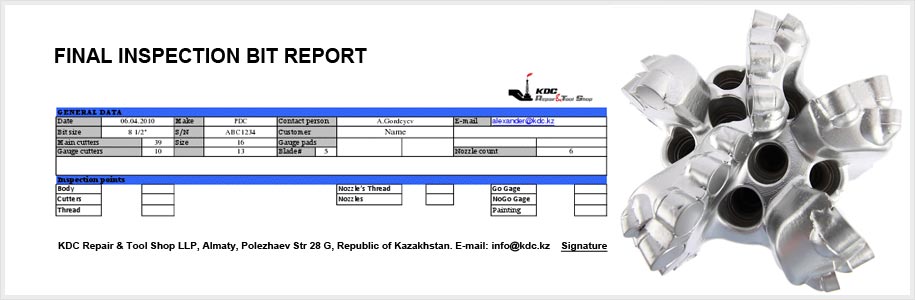

Now the bit is ready for inspection. A detailed inspection report will be made for each item of the bit. The customer will received an inspection report with quotation for repair. We offer different cutter types for the different drilling applications and bit types. Interaction from the customer is very important in this stage to repair the bit as per customer’s application requirements.

After the customer agreement for repair, the repair process will start. Damaged cutters will be removed and replaced by new ones. Also bit bodies will be repaired and hardfacing will be applied during this process. After the brazing process the bit will be cooled prior to the next process.

This is the last process of repair. The bit will be grinded to remove any particles that be may be left on the bit after the brazing process.

After the complete repair process the bit will be checked for the final quality control.

As a last stage before the bit leaves the shop, the bit will be painted and packed. Also transport back and forth to the drilling location or customer warehouse can be arranged.